Mahsulot tavsifi:

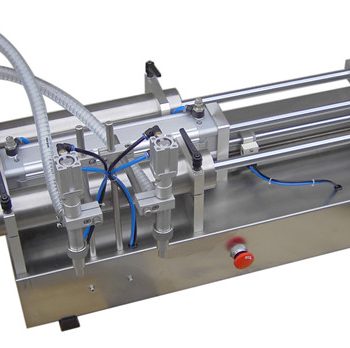

Ushbu mashina yuqori texnologiyali uskunadir, u ilg'or xorijiy texnologiyalarni joriy etish va GMP talablarini inobatga olgan holda muvaffaqiyatli ishlab chiqilgan va ishlab chiqilgan, adolatli tuzilish, to'liq funktsiya, qulay ishlash, to'g'ri to'ldirish, barqaror ishlash, shuningdek past shovqin xususiyatlariga ega. U suyuq yoki yuqori tezlikda materiallarni to'ldirishdan avtomatik ravishda partiyani bosib chiqarishgacha (ishlab chiqarish sanasini qo'shgan holda) ishlaydigan PLC boshqaruvchisi bilan ishlaydi, bu kosmetika, dorixona, oziq-ovqat mahsulotlari, elimlar va hokazolarda ALU naychasi, plastmassa naycha va ko'p naychalarni to'ldirish va muhrlash uchun ideal uskunalar. GMP standartiga mos keladigan sanoat tarmoqlari.

Xususiyatlari:

1. LCD displeyli PLC va tugmachalar bilan ishlaydigan yuqori darajadagi ekran, oson ishlashi va ko'proq insonparvarligi bilan qadam tezligini sozlash, parametrlarni sozlash, o'chirish, bosim ko'rsatkichi va ishlamay qolish displeyi.

2. Quvurni etkazib berish, fotoelektr registri, inert gazni to'ldirish (ixtiyoriy), materialni to'ldirish va muhrlash, partiyani bosib chiqarish, tayyor mahsulotni ishlab chiqarish avtomatik ravishda bajariladi.

3. Yuqori aniqlikdagi fotoelektr registri xromatik aberatsiya hajmini kamaytirdi.

4. Tashqi holatini sozlash qismlari, raqamli displey joylashuvi, qulay va aniq sozlash (turli xil mahsulotlar ishlab chiqarish uchun mos).

5. Mexanik, fotoelektron, elektr, pnevmatik integrativ boshqaruv, naychaga hech qanday to'ldirish vazifasi bo'lmaydi; Quvurlardagi xato holati yoki bosim juda past bo'lsa, himoya eshikni ochganda avtomatik to'xtash mashinasi.

| Model | GF-400 A | GF-400 B |

| Quvur materiallari | Metall naycha, ALU naycha | Plastik naycha, aralash kolba |

| Quvurlar diametri | 10-42 mm | 10-60 mm |

| Tub uzunligi | 50-250 (sozlanishi mumkin) | 50-250 (sozlanishi mumkin) |

| To'ldirish hajmi | 5-500ml / filial (sozlanishi) | 5-800ml / filial (sozlanishi) |

| To'ldirish aniqligi | ≤ ± 1% | ≤ ± 1% |

| Tezlik | 3-10 r / min | 2,5-7 r / min |

| Mahsulot hajmi | 30-60 PC / min | 30-60 PC / min |

| Havo ta'minoti | 0,55-0,65mpa | 0,55-0,65mpa |

| Dvigatel kuchi | 2kw (380V / 220V 50Hz) | 2kw (380V / 220V 50Hz) |

| Issiqlik sızdırmazlık kuchi | 3KVt | 3KVt |

| Umumiy o'lchov | 2620 × 1020 × 1980 mm | 2620 × 1020 × 1980 mm |

| Mashinaning og'irligi | 1100 kg | 1100 kg |

Asosiy ma'lumotlar

Ilova: Yopish

Turlarni shakllantirish: shishani shakllantirish

Haydovchi turi: elektr

Qadoqlash: yumshoq naycha

Dvigatelning kuchi: 2 kVt (380V / 220V 50Hz)

Umumiy o'lcham: 2620 × 1020 × 1980mm

Trademark: VKPAK

Kelib chiqishi: Shanxay, Xitoy

Avtomatik daraja: Avtomatik

Turi: to'ldirish va muhrlash mashinasi

Formalash funktsiyasi: to'ldirish

Materiallar turi: Yopish

Mahsulot hajmi: 30-60 kompyuter / min

Issiqlik muhrlanish kuchi: 3kw

Mashinaning vazni: 1100kg

Xususiyat: Idoralar

A cream tube filling packing machine is a type of packaging machinery designed for filling and packaging various types of creams, gels, pastes, and other similar products into tubes. This type of machine typically consists of several components, including a tube feeder, filling unit, sealing unit, and cutting unit. The overall production process is automated, which ensures the accuracy and consistency of the fill, as well as the speed of production.

The specific features and specifications of a cream tube filling packing machine may vary depending on the manufacturer and the intended application, but some common features include:

High precision: The filling system is designed to be accurate, with the ability to fill the exact amount of product specified, with minimal waste.

Versatility: The machine can be used for filling and packaging a wide range of products, including creams, gels, pastes, and other similar products.

Hygiene: The machine is designed to meet hygiene standards, with components made from food-grade stainless steel and other non-corrosive materials. The filling system is also designed to prevent contamination, ensuring the safety and quality of the product.

Easy to operate: The machine is typically user-friendly, with intuitive controls and easy to follow instructions. The system is also designed to be easy to maintain, with minimal downtime required for cleaning and servicing.

High production rates: A cream tube filling packing machine is designed to work at high production rates, with the capability of filling and packaging hundreds or even thousands of tubes per hour.

Overall, a cream tube filling packing machine is an efficient and reliable solution for filling and packaging various types of creams and gels into tubes. It is a popular choice for manufacturers who need to package products for retail or commercial use, with the ability to meet high standards of accuracy, consistency, and hygiene.